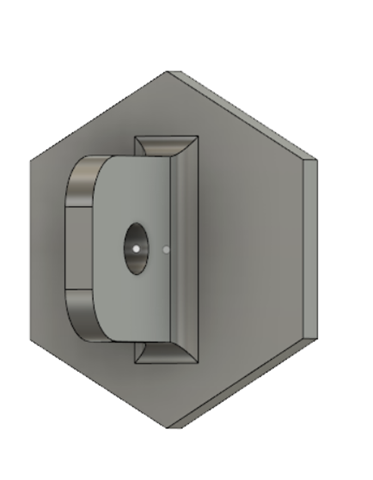

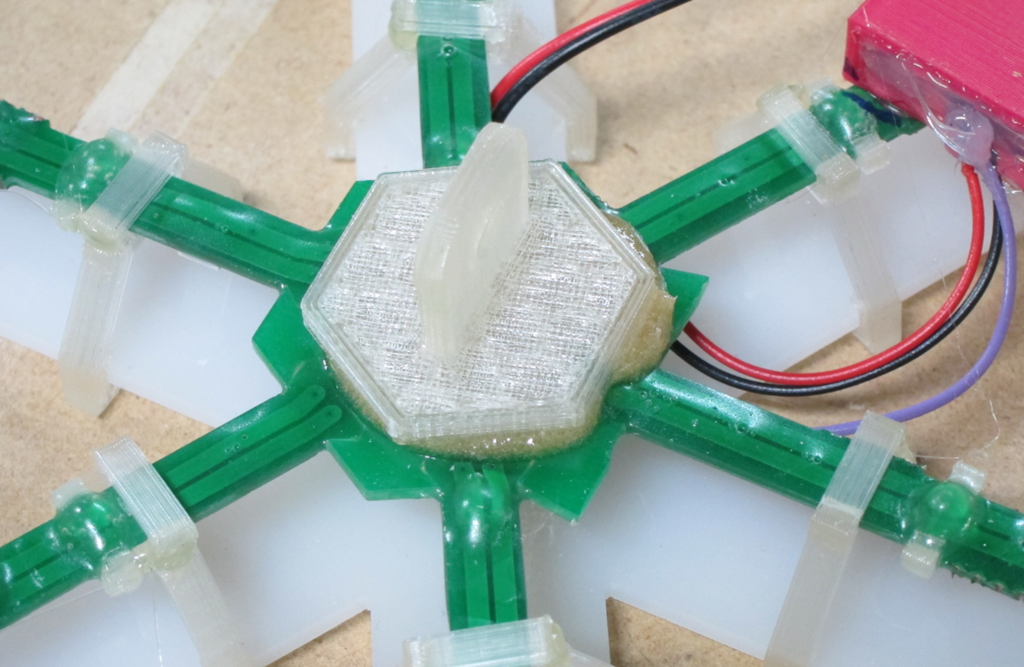

I had a small gluing project to do today; I needed to attach a small 3d printed pad eye to the back of my animated LED snowflakes (project info here). The pad eye looks like this:

The pad eye is printed out of PLA and is about 1.25” inches across. I needed to attach it to the back of a printed circuit board. Which would make my adhesive choice seem simple, but there are two complications:

- There are wires soldered onto the PC board and that part of the board is not flat.

- The boards are waterproofed in epoxy, and the coating is has some variation – perhaps 1/16”

That means that I need an adhesive that will bond well to the PLA and epoxy and fill the gap in between the two surfaces.

My first thought was to heat up the hot glue gun and use it. It works fine as a gap filler, but it’s not great in a thin layer between two big surfaces; it’s too easy to have the glue cool too fast and not really bond to the surfaces.

My next thought was to use epoxy. I have several epoxies in my workroom; they are the small hobby shop versions that come in small tubes or bottles. I really don’t like them very much; it’s hard to get the mixture ratio right and in this application they tend to be too runny. And they smell.

Out in the garage I have my serious epoxy:

That’s leftover from a custom subwoofer project I did a while back. It’s really easy to use; one pump of resin plus one pump of hardener and just mix it together. I have the 206 hardener, which is classified as a “slow” hardener; 20-25 minutes of pot life (useful life after you mix it before it starts to thicken up too much), 10-15 hour cure, 1-4 days to maximum strength. The nice part about serious epoxy is that it’s tunable; you can use the 205 fast hardener which cures in 6-8 hours or the 209 extra slow hardener with much longer pot life and a slower cure.

Anyway, I really like this epoxy, but it is really runny, so it won’t work for this application.

Or will it?

Welcome to the wonderful world of epoxy fillers. There are a lot of different fillers out there – here’s a nice article by System 3 (another epoxy company) that describes them and why you would use them – that can modify the properties of epoxy considerable. For this use, I am interested in fillers that modify the viscosity of the epoxy, and specifically interested in fillers that make it thixotropic.

A thixotropic fluid is one that flows when you apply stress to it and then stops flowing when that stress is used. The most common example used is catsup, but I think that peanut butter is a better example; you can make it flow around but when you are done, it sticks where you want it. And it’s sticky, like epoxy. That is a wonderful property for an adhesive; just stick it where you want and it will stay there until it cures; no drips or sags.

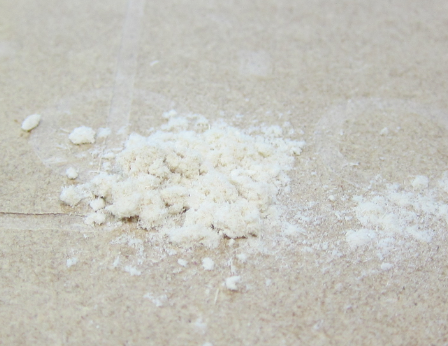

There are a few common thixotropic fillers; ground silica (known as cab-o-sil or aerosil), plastic minifibers, and – my personal favorite – wood flour.

This particular wood flour came from the little bag on my random-orbit sander, which is why I like wood flour; I generally have it sitting around. Note that it needs to be very fine; sawdust from cutting will probably be too coarse. The wood flour will make the epoxy wood colored; if you would prefer it to be closer to clear, the ground silica or plastic minifibers will work better.

Mixing it is pretty simple; mix up the epoxy, add a little wood flour, mix it up, and examine its physical properties. If it drips off of your mixing device, you need more wood flour. If it sticks like the aforementioned peanut butter, you are done.

I like to use small plastic cups for my epoxy mixing and plastic silverware; they are easy to find and disposable, and since I use the dispenser pumps to get the right amount, I don’t need to do any measuring in the cups.

All that is left to butter the epoxy onto the PLA pieces, gently press them in the proper position, and wait for the epoxy to cure.